What is worse: lacking data about a project before construction begins, or suffering from poor communication between stakeholders? Both are symptoms of an approach that overlooks proper coordination. This article explores five common coordination issues and a proven approach to mitigate them.

#1 Neglecting coordination in the early stages of design

One of the most frequent errors in design and coordination between Architecture and MEP (Mechanical, Electrical, and Plumbing) is the failure to coordinate early on among the different stakeholders. Treating MEP systems as an afterthought can lead to clashes between architectural and MEP elements, disrupting the entire design and construction process.

Emphasizing an integrated design approach from the project's inception ensures that all parties work and collaborate effectively. This approach minimizes conflicts, reduces the need for rework, and keeps your project on track.

Effective early coordination not only saves time but also improves cost control.

This year, we supported several projects in Dubai during the Schematic Design (SD) and Design Development (DD) phases. Because coordination was prioritized early, we could monitor the projects' evolution and deliver well-coordinated outcomes. Starting coordination once construction is underway, on the other hand, often leads to delays and cost overruns.

#2 Insufficient documentation

Incomplete or inaccurate documentation can lead to misinterpretation, delays, and even conflicts during construction. Clear, precise, and comprehensive documentation of the architectural and MEP design is important for the smooth execution of the project. A team with good experience in the field and a focus on quality ensures that the documentation is complete and accurate, reducing project risks and streamlining the construction process.

#3 Improper equipment sizing

Correct equipment sizing is a critical element in MEP design that directly impacts the overall efficiency and performance of a project. Oversizing or undersizing equipment can lead to many problems and associated costs. In addition, improper sizing can prevent the necessary space from being designated for the installation and proper operation of equipment.

#4 Poor or insufficient communication

When coordination is poorly managed and changes or modifications aren't communicated on time, the various teams involved do not have the correct information. This leads to rework, lost time, and widespread frustration caused by misinformation.

Collaborative work requires a clear, precise, and orderly communication process to achieve optimal project coordination.

#5 Ignoring technological advancements

The construction industry is in a constant state of evolution. Failing to keep up with the latest technological advancements can put your project at a significant disadvantage.

A technology-driven approach is now central to successful project delivery. Building Information Modeling (BIM) and Virtual Design and Construction (VDC) enhance planning and execution by offering a comprehensive view of a building's design before construction begins. These technologies revolutionize traditional approaches, enabling better collaboration, fewer errors, and stronger project management.

Technology: the great ally in coordination

When combined with Point Cloud Technology, Virtual Reality (VR) takes project understanding to a new level. Point Cloud captures existing conditions in three dimensions, providing precision and accuracy for renovation and upgrade projects. This results in detailed as-built models, helping future maintenance teams "see through walls" and locate systems long after construction is complete.

At Corbis, our coordination process is led by specialists and embraces technology as a part of our DNA, supported by tools such as:

-Heat Maps: Based on our previous experience and project-specific criteria, we create a Heatmap to identify critical areas where we must focus our analysis.

- Navisworks: This software allows us to combine and analyze information from all disciplines involved in the project.

-Revit: Identified clashes are transferred to Revit to create a 3D model that clearly represents the potential issues.

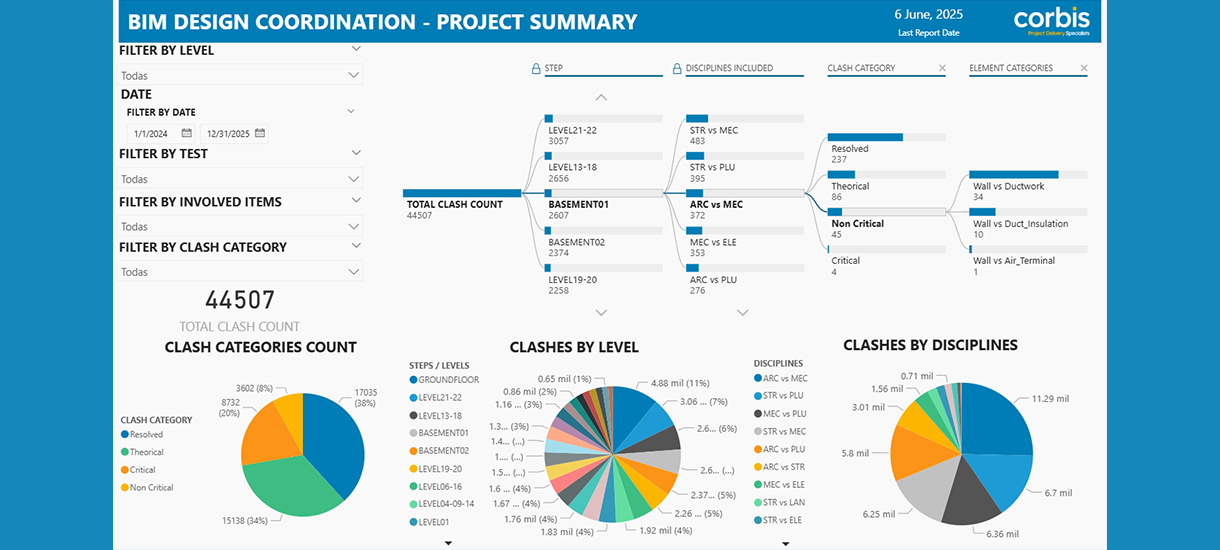

-Power BI: We use Power BI to generate user-friendly reports that classify clashes by group. This makes it easier for all design team members to understand and address the issues.

Avoiding mistakes is only the beginning. The future of construction depends on a proactive mindset. Success isn't just about adopting the right technology; it's about combining it with seamless human collaboration.

With this approach, coordination evolves from a simple task into a powerful strategy that drives innovation. In the end, the most remarkable projects are built not just with steel and glass, but on the foundation of strong teamwork.

Do you have a project in your pipeline? Let’s talk before your project needs it.